HACCP labels: 7 steps to the right label

HACCP is a risk assessment for food. The term "HACCP" originally comes from American space

travel and stands for "Hazard Analysis and Critical Control Points." In space travel, it is not

possible to return spoiled food and replace it with unspoiled food. The failure of a mission due

to food poisoning was considered an unacceptable risk.

One of the components of the HACCP approach is control. Control of the various parts of the

process that the food goes through. In many cases, labels play an important role. Labels on

which the necessary information is printed. Labels featuring your logo and pre-filled with the

required information fields.

Food industry

Nowadays, HACCP rules apply to companies in the food industry. This includes distribution,

preparation, processing, treatment, and packaging of food products. All these companies must

identify and analyze food hazards. In the European Union, this inventory model was

introduced to ensure that the production and processing of food products carry as little

risk of contamination as possible.

HACCP is not a written law; it is based on seven core principles. These are described below.

Every company involved in the food chain is subject to them.

Hazard Analysis and Critical Control Points (HACCP)

The HACCP system has 7 core principles:

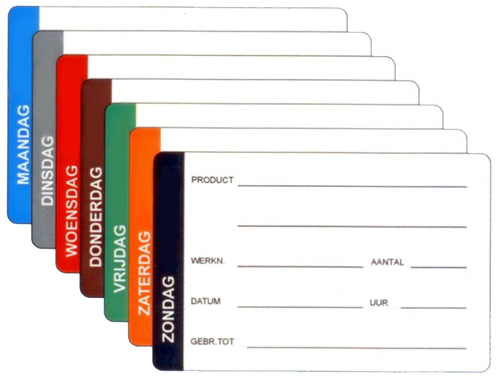

HACCP labels

HACCP labels can be printed in various full-color options with fill-in fields for the

desired product information. Additionally, you can have the labels pre-printed with your own

house style. It is practical to have these labels produced on rolls, allowing you to use a

dispenser to store the different rolls.

For identification, it is possible to use different colors or shapes for the labels each

day, for each product, or for each product group. Depending on the surface or environment

where the labels are used, you can choose the most suitable material and lining (ask our

advisors). HACCP labels are essential in the food industry to prevent contamination. Do you

already use the most practical HACCP labels?

Exclusive Offers and Free Tips!

Stay informed and never miss out on offers, handy tips, or free templates.

Thank you! You have successfully subscribed to our newsletter.

.png)